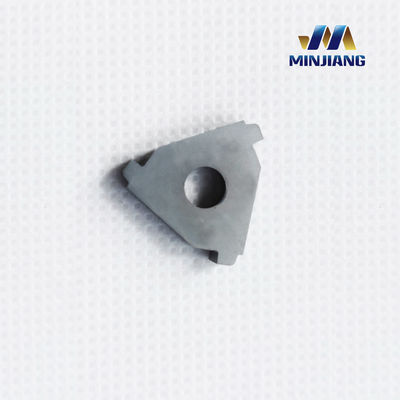

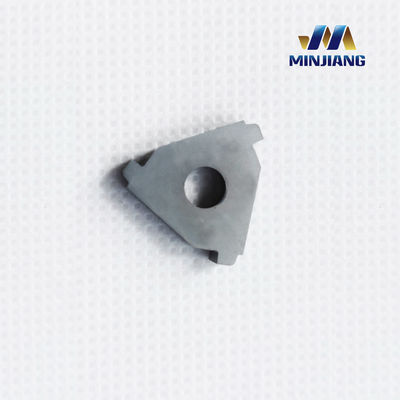

Przedłużona żywotność narzędzia 22NRBUT Wkładki do gwintowania rur olejowych do precyzyjnej obróbki

Opis

Wkładki do gwintowania z węglika spiekanego to precyzyjne narzędzia skrawające używane do tworzenia gwintów wewnętrznych w materiałach takich jak stal, stal nierdzewna, aluminium i tworzywa sztuczne. Wykonane z trwałego węglika spiekanego z powłokami odpornymi na zużycie, zapewniają wysoką dokładność, szybką obróbkę i przedłużoną żywotność narzędzia. Montowane w uchwytach narzędziowych, zapewniają wydajne i niezawodne cięcie gwintów.

Cechy produktu

Wysoka-jakość gwintowania: Produkcja gwintów z wąskimi tolerancjami i wykorzystaniem doskonałych materiałów w celu zapewnienia trwałości, niezawodności i stałej wydajności.

Ekonomiczne: Optymalizacja procesów gwintowania w celu zmniejszenia marnotrawstwa materiału, czasu pracy i ogólnych kosztów produkcji bez kompromisów w zakresie jakości.

Długa żywotność narzędzia: Narzędzia do gwintowania, które są odporne na zużycie, zachowują ostrość i działają niezawodnie przez długi czas — minimalizując przestoje i koszty wymiany.

Łatwe w użyciu: Intuicyjne narzędzia i metody gwintowania, które wymagają minimalnego szkolenia, skracając czas konfiguracji i ograniczając błędy operatora.

Precyzyjne gwintowanie: Gwinty obrabiane zgodnie z dokładnymi specyfikacjami przy użyciu zaawansowanych narzędzi i technik, zapewniające powtarzalną dokładność w krytycznych zastosowaniach.

Materiały

Wybór materiałów na wkładki do cięcia gwintów różni się w zależności od materiału obrabianego przedmiotu w celu uzyskania lepszej wydajności cięcia.

Niektóre opcjonalne Gatunek węglika spiekanego:

| Gatunek metalu |

wydajność i zastosowanie |

|

MC1

|

MC1 wykazuje wyjątkową czerwoną twardość matrycy i niezwykłą wytrzymałość, co sprawia, że idealnie nadaje się do obróbki na wysoko wydajnych maszynach do gwintowania. Ponadto jest doskonale kompatybilny z wymaganiami gwintowania rur olejowych, obudów i złączy, które należą do średnich gatunków stali i drugorzędnych gatunków stali wysokiej, obejmujących materiały takie jak J55, K55, N80, L80.

|

| MC2 |

MC2 charakteryzuje się wysoką wytrzymałością matrycy, doskonałą czerwoną twardością i dobrą odpornością na uderzenia. Nadaje się do wysoko wydajnej obróbki gwintów rur olejowych, obudów i złączy ze stali średniej i wysokiej, takich jak N80 i P110.

|

| MC3 |

MC3 charakteryzuje się dobrymi ogólnymi właściwościami mechanicznymi w swojej matrycy, a także stabilną wydajnością cięcia. Nadaje się do wysoko wydajnej obróbki gwintów rur olejowych, obudów i złączy, które należą do niskich, średnich i drugorzędnych gatunków stali wysokiej, takich jak H40, J55, M65, C75, N80 i podobne specyfikacje.

|

| P35 |

P35 wykorzystuje matrycę o wysokiej wytrzymałości i doskonałej czerwonej twardości, dzięki czemu nadaje się do obróbki gwintów rur wiertniczych, kołnierzy wiertniczych, prętów pompowych i innego powiązanego sprzętu.

|

| YT15 |

W zależności od konkretnego zastosowania może być powlekany lub niepowlekany i posiada dobrą czerwoną twardość i wytrzymałość. Nadaje się do produkcji specjalistycznych łamaczy wiórów do grzebieni do cięcia gwintów i innych narzędzi skrawających.

|

| Materiał S |

Wykazuje doskonałą odporność na zużycie i wysokotemperaturową czerwoną twardość, dzięki czemu nadaje się do gwintowania wewnętrznego stali średnio- i wysokostopowych.

|

Od ponad 30 lat Minjiang jest zaufanym partnerem w branży, znanym z niezawodności i doskonałości. Nasza pasja do jakości i innowacji wyróżnia nas na tle konkurencji, wspierana przez zespół ekspertów oddanych dostarczaniu rozwiązań dostosowanych do unikalnych potrzeb każdego klienta. Zobowiązani do doskonałej wydajności, wykorzystujemy najnowocześniejszą technologię i zrównoważone materiały, aby zmaksymalizować wydajność i wpływ. Oprócz produktów, jesteśmy dumni z wyjątkowej obsługi klienta — zapewniając bezproblemowe, bezproblemowe doświadczenie na każdym kroku. Z Minjiang zawsze możesz oczekiwać najwyższej jakości, niezrównanej niezawodności i obsługi, na której możesz polegać.

FAQ

1. P: Czy oferujecie produkty na zamówienie?

O: Tak, często wykonujemy produkty na zamówienie.

2. P: Czy dostarczacie darmowe próbki?

O: Możemy dostarczyć darmowe próbki, ale nie ponosimy kosztów transportu.

3. P: Jakie są korzyści z używania wkładek do gwintowania z węglika spiekanego?

O: Wkładki do gwintowania z węglika spiekanego oferują kilka korzyści w porównaniu z tradycyjnymi metodami gwintowania. Są bardzo precyzyjne, zapewniają doskonałe wykończenie powierzchni i są w stanie wytwarzać wysoką dokładność gwintów przy minimalnym zużyciu narzędzia. Wkładki do gwintowania z węglika spiekanego wymagają również mniejszego momentu obrotowego i mocy do wytwarzania gwintów, co skraca czas cięcia i koszty.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!